In the H2-Reallabor Burghausen – ChemDelta Bavaria project, solutions on how the chemical industry can realize the climate-neutral transformation towards a sustainable economy are to be developed.

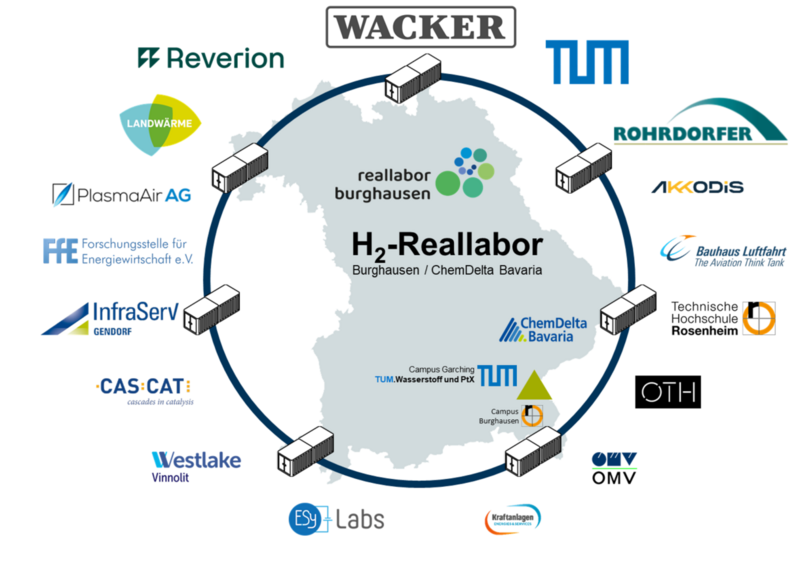

Sustainable in this case means to abstain from the use of fossil resources such as natural gas. Renewable hydrogen is intended to play a major role in this regard. For this purpose, 35 renowned partners from science and industry have joined forces in a 4-year project.

In the context of the joint project, Bauhaus Luftfahrt is evaluating various production processes for renewable kerosene that can contribute to a sustainable fuel supply for Bavarian air transport. The focus is on regional value chains and the transformation of the refinery in Burghausen, which, through a direct pipeline connection, covers a large part of the kerosene demand of Munich Airport.

The work of Bauhaus Luftfahrt focuses on the question of how the Bavarian aviation system can be supplied with sustainable aviation fuels (SAF). This task is addressed from two perspectives. On the one hand, the current and future fuel demand of Bavarian airports is determined, and on the other hand, the local potential for fuel production is analyzed.

A major focus here will also be on the integration of existing infrastructure, such as the refinery in Burghausen and its pipeline connection to Munich Airport. Based on external influencing factors, such as political measures or the future orientation of the industry in the Bavarian Chemical Triangle, various scenarios are created. Depending on the scenario, in addition to local fuel production, imports may also occur. These imports can either include direct fuel or precursors, such as hydrogen or methanol, which are then converted into SAF in a local fuel production facility. To evaluate the different scenarios, the following metrics are used:

- Production potential

- Fuel production costs

- CO2-equivalent emissions of fuel production

The results of the scenario analysis ultimately feed into a roadmap, which is intended to outline various transformation paths for the chemical industry in the Bavarian Chemical Triangle.

Coordination:

H2-Reallabor Burghausen – ChemDelta Bavaria

Scientific partners:

Technische Universität München

Technische Hochschule Rosenheim

Ostbayerische Technische Hochschule Regensburg

Forschungsstelle für Energiewirtschaft e.V.

Industry partners:

The underlying project was funded by the German Federal Ministry of Education and Research

under the funding code 03SF0705B.