Aviation has set the ambitious target to achieve “net-zero carbon emissions” by 2050 [1]. This transition requires the substitution of fossil jet fuel with regenerative fuels within only two and a half decades. Due to the required scale, it is expected that a significant share of future aviation fuel supply will be based on green H2 from solar and wind energy. Two important options for H2 use in aviation are synthetic kerosenes from Power-to-Liquid (PtL) pathways and liquid hydrogen (LH2) for direct use as aviation fuel.

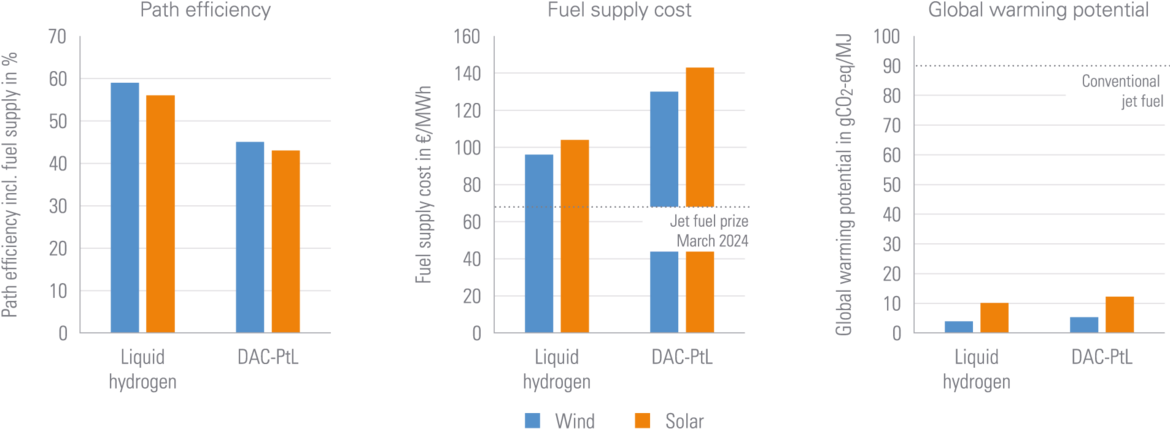

Bauhaus Luftfahrt compared fuel production and supply from two exemplary locations in Ireland (wind) and Morocco (solar) to Frankfurt airport. It was assumed that hydrogen is liquefied at the production site and LH2 is then transported by ship and truck to the airport, while synthetic fuel is produced from atmospheric CO2 (Direct Air Capture, DAC) via a Fischer-Tropsch based PtL pathway at the hydrogen production site.

The process modelling and techno-economic comparison resulted in a significant advantage both in energy conversion efficiency and relative cost advantage of about 30 % for LH2 versus DAC-PtL supply pathways. The quantification of the supply costs, however, involves higher uncertainty. Life-cycle analyses confirmed that both LH2 and DAC-PtL can achieve signifi cant greenhouse-gas emission reduction of more than 85 % compared to conventional jet fuel when produced from solar or wind energy.

The results indicate that both LH2 and DAC-PtL are potential longterm solutions with much-reduced climate impact. An introduction of both sustainable fuel options needs to be supported, as estimated supply costs are above current price levels for crudeoil based kerosene. The extent of support for either DAC-PtL or LH2 remains an important strategic question for aviation.

[1] 41st ICAO Assembly, October 2022: Long-term global aspirational goal of net-zero carbon emissions by 2050.