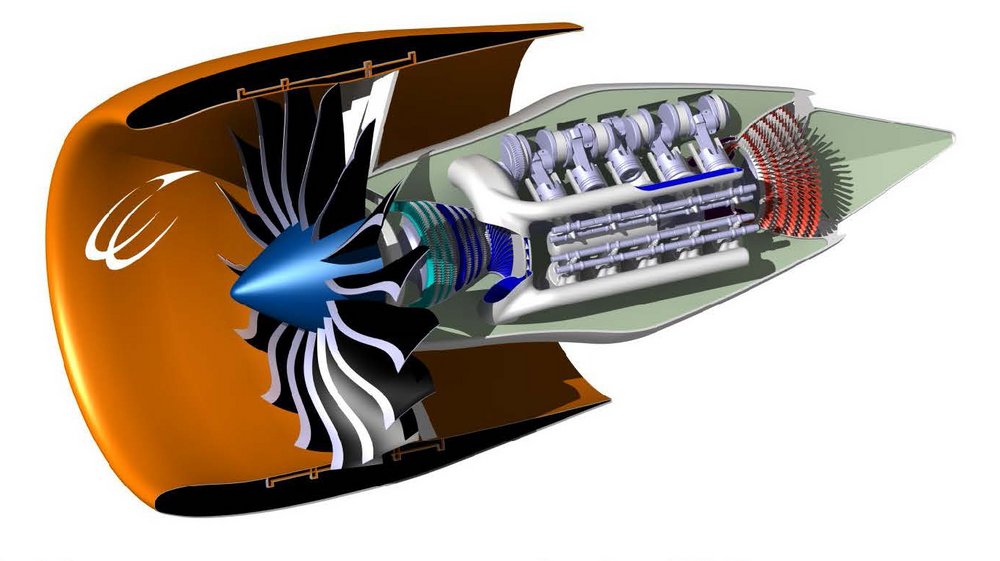

The Composite Cycle Engine (CCE) concept incorporates piston engine technology into the core of an aircraft turbo engine. Assuming an entry into service in 2050, fuel burn improvements up to 50% relative to year 2000 turbofan technology (11% relative to year 2050 advanced GTF technology respectively) can be reached.

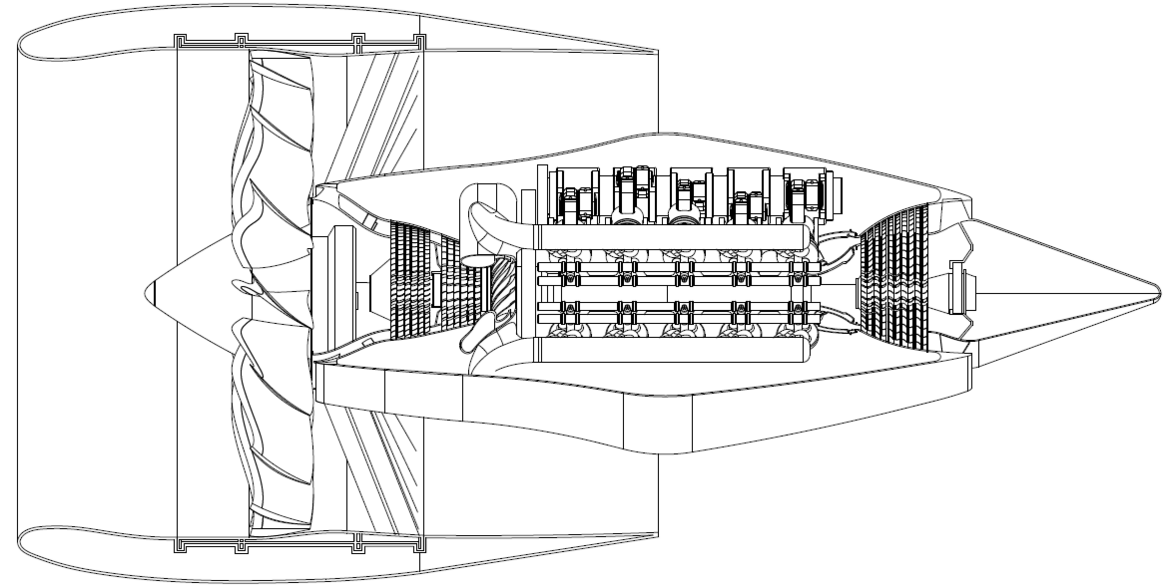

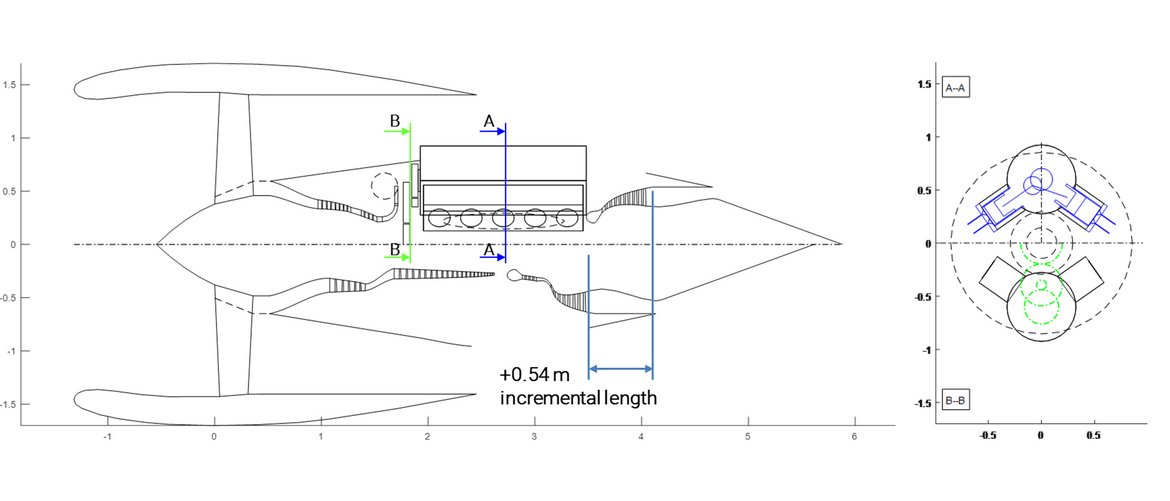

The piston engines increase thermal efficiency by using non-stationary isochoric-isobaric combustion, which enables higher peak pressures and temperatures within the core engine. In the current design, the piston engine is connected with the high pressure spool and powers the axial-radial high pressure compressor (dark blue). The low pressure system is similar to a conventional geared turbofan (GTF) architecture. This way, the outstanding power to weight ratio of low pressure turbines can be fully utilized and an ultra-high bypass ratio is realized.

System Details

- Ultra-high bypass ratio Composite Cycle Engine technology

- Piston engine powers high pressure shaft

- No High Pressure Turbine

- No power- and bleed-offtakes

- Slim line nacelle design

- Buffering volumes to reduce interaction of stationary operating turbo components and non-stationary piston engine

Geometry and Weights

| Fan diameter Engine length Engine weight Piston engine weight Stage count Number of Fan blades Gear Ratio (Fan) Number of pistons Gear Ratio (Piston) Piston bore Piston stroke Piston vmean Piston Compression Ratio | 2.87 m 5.88 m 7.27 t 2.45 t 1-3-3-1-5 16 5.3 20 3.3 0.2 m 0.2 m 18 m/s 7.3 |

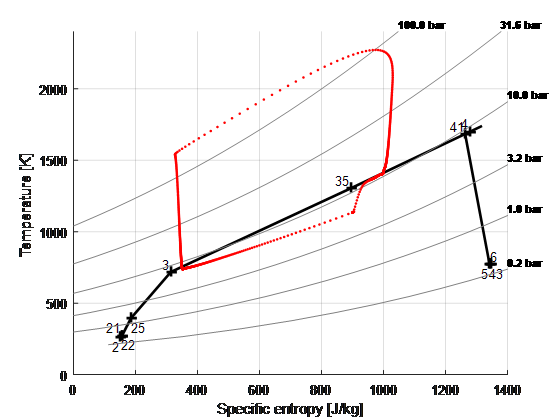

The T-s diagram of the CCE - thermodynamic cycle illustrates the high peak pressure and peak temperature that can be realized with a CCE.

The red dotted line represents the non-stationary thermodynamic cycle of the piston engine which takes place between the thermodynamic station 3 and 35 of the total CCE cycle representation (black line with typical station nomenclature).

The research leading to this Mock-up has received funding from the European Union's Horizon 2020 research and innovation programme under agreement No. 633436, Project ULTIMATE (Ultra Low emission Technology Innovations for Mid-century Aircraft Turbine Engines).