The use of green hydrogen (H2) in aviation requires its provision in liquid form (LH2). Centralised production and liquefaction of H2 at suitable locations favoured by cost-effectively accessible renewable energies and economies of scale, necessitates the transport of LH2 in cryogenic tanks to airports. Given the cross-sectoral transition towards a hydrogen economy and the planned Europe-wide distribution of gaseous hydrogen (GH2) through repurposed and new pipelines, Bauhaus Luftfahrt has analysed technology perspectives for LH2 and GH2 transport, with a focus on energy requirements and capacity.

Transporting LH2 over long distances proved to be more energy-efficient, especially with future use of boil-off gas for propulsion. For shorter distances, GH2 transport may be more advantageous, depending on the technology mix and the extent of the more energy intensive land transport compared to sea transport. A key finding was that repurposed pipelines, while cheaper than new ones, substantially reduce the break-even distance.

The thermodynamic analysis showed that the rougher inner surface of the pipes significantly increases the energy requirement for recompressing GH2 to compensate for friction losses. However, a moderate reduction in the transport quantity can compensate for this additional energy consumption, but always at the expense of the total costs. New composite pipelines, thanks to their smoother surface as well as high strength and flexibility, offer advantages in efficiency, capacity and cost compared to traditional steel pipelines.

These findings highlight the aviation sector’s need for parallel development of advanced LH2 and GH2 transport infrastructure and inform integrated studies for optimised hydrogen supply.

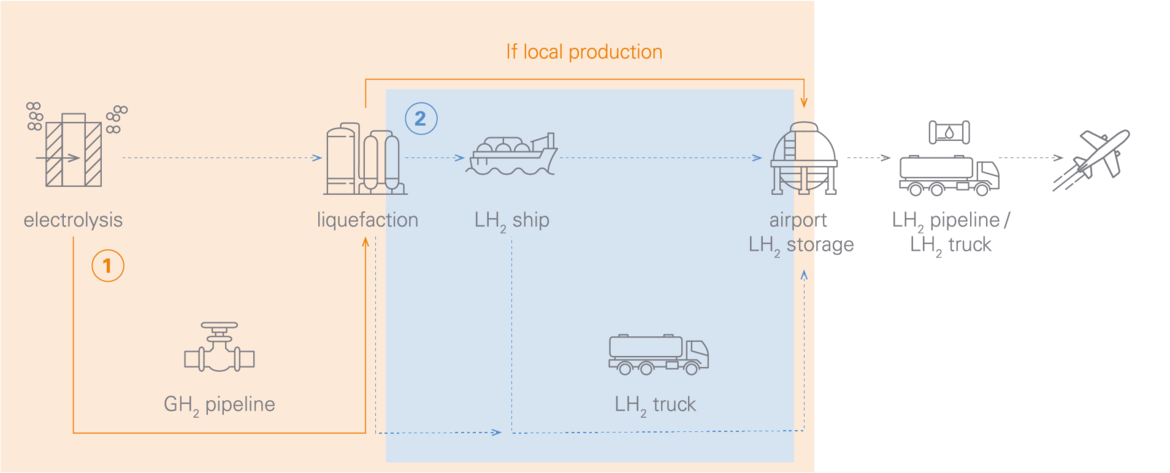

Life cycle of Green Hydrogen with different transportation options (shaded areas)

Electrolysis-derived GH2 is 1) transported via GH2 pipelines and then liquefied close to the point of use or 2) directly liquefied, e. g. at the production location, followed by LH2 transport via sea and / or land to the airport.

Hydrogen transport options

If a reciprocating compressor is used to compensate for pressure drop along GH2 pipes, LH2 transport is preferred regardless of the distance. With the more efficient centrifugal compressor, the break-even distance depends on the inner surface quality of the pipeline and the transport share of the truck – e. g. 600 km (repurposed pipelines) and 900 km (new pipelines) for a truck transport share of 500 km.

L. Koops, Gas Pipeline versus Liquid Hydrogen Transport – Perspectives for Technologies, Energy Demand and Transportation Capacity, and Implications for Aviation, DLRK, Stuttgart, 2023